Shri Karvir Nivassini Mahalaxmi Ispat Pvt. Ltd. is a widely known and Maharashtra located company, which has been working as Manufacturer & Exporter and bringing forth TMT Reinforcement Steel Bars, TMT Steel Bars, TMT Reinforcement Bars (of sizes 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 28mm, 32mm) and TMT Quenching Systems. All our offerings are known for their strength, life and built. To produce excellent quality products, we have equipped our production unit with modern machines. Mr. Jitendra P. Gandhi is the Director of this company who has been promoting it on Indian and International platforms to aid customers residing in Indian and International markets in buying quality at reasonable rates.

From a wide variety of products we manufactured and supplied, TMT Steel Bars of various lengths and diameters gained most appreciation and worldwide acceptance because of quality. To manufacture these bars, we have recently invested a large sum of money in TEMPCORE technology. This technology is needless to say modern and gives better strength and elongation to products. Thermo quenching system as well as machinery used provides perfect mechanical strength to our offerings, as per IS 1786. The complete system is automated, thus needless to cite it is controlled by computers. The new unit of our associated company commissioned in the year 2006 July.

Manufacturing Capacity & Stock level

The operational hours of our company are 10 hours. The amount of products we produce in a month is approx 300 tonnes. 8Mm to 32mm of steel bars TMT (Thermo metallurgical treatment) steel bars are produced. To meet bulk order requirement of customers, we stock around 100 tonnes of material. As per the size of the order and for fast delivery of products, the working hours of our employees are increased. We sell products without piling stocks. If we calculate our turnover on a monthly basis, it comes to be nearly Rs. 800 Lacs.

Quality

We have an in-house quality checking laboratory in Kolhapur. To analyze steel, we have installed Q4 Tasman 130 Bruker Germany made Spectrometer. C, Mn, S, Phos, Cr and other elements shows the strength and quality in our offered TMT Steel Bars. We perform pre and post quality inspection to ensure quality of our offerings. Since, our offerings are checked stringently, we assure our customers that every product is high on quality.

Process

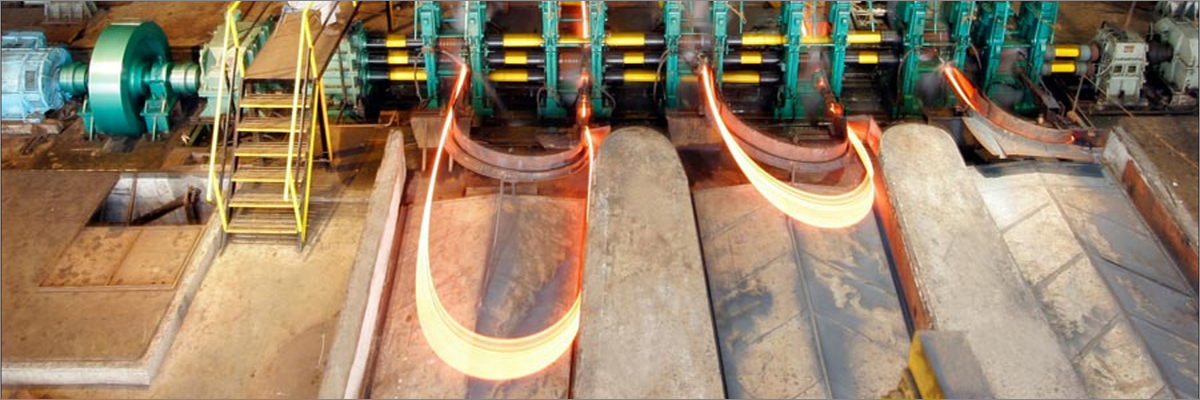

The TMT (Thermo metallurgical treatment) is given to hot bar by water. In our Kolhaour based rolling mill, the billets or ingots are heated using reheating furnace and coiled in different rolls. The bar of the final stand is dependent on water treatment. Our manufacturing process involves the following processes:

- Quenching- Hot rolled bar is quenched through nozzles by water injection. This makes the soft surface layer hard Martensite.

- Self Tempering- It is done when steel bar vacates quenching box where temperature of the center is higher than surface. The heat is flowed from the core to surface which hardens of the surface and gives a structure Tempered Martensite. This structure is strong and hard. The center is still solid at this point.

- Atmospheric Cooling- This is done on a cooling bed, where the solid center is moved to a ductile ferrite-pearlite. At the end of this process, the structure comprise of a collection of hard and tough outer layer of tempered martensite.

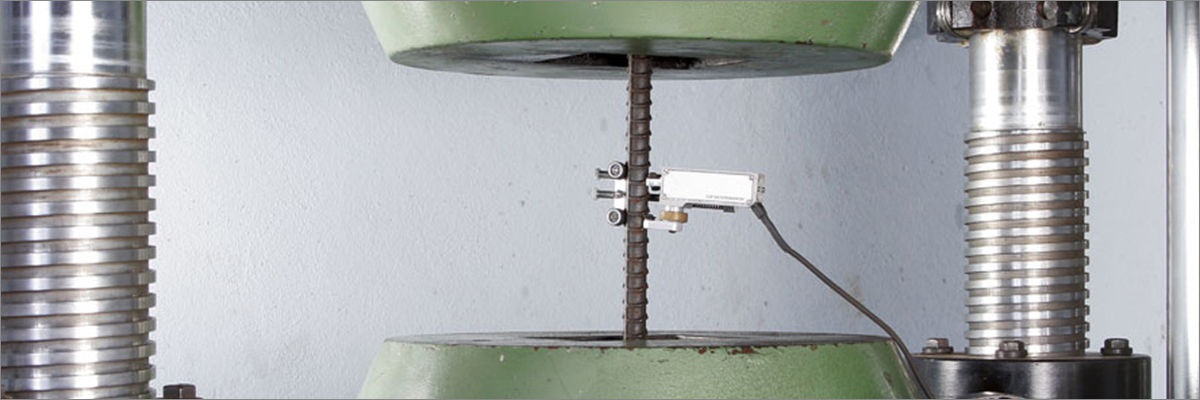

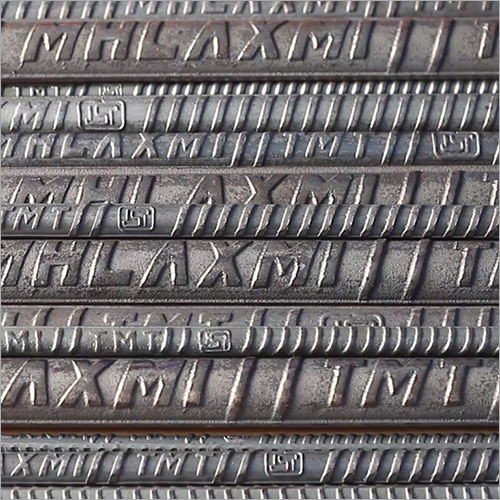

During TMT Bars processing and after every 30 minutes, we take bar samples for inspection. Our in- house testing laboratory (chemical and physical) managed by quality controllers is developed to test these bars. For reliable testing result (tests- Elongation, Tensile and ultimate strengths), we have installed UTS machine of 60 and 100 tonnes. For better bondage, the lugs are engraved on CNC machine. MHLAXMI is marked at all bars at every meter length. The homogeneous metallurgical transformation is a result of 12 meter length of quenching box.

Clients

Below listed are our clients:

|

Builders, Developers & Contractors |

Traders |

||

|

Name of Customer |

City |

Name of Customer |

City |

|

Marigold Properties |

Bengaluru |

Chindak Associates |

Belgaum |

|

CRD Realtors |

Chiplun |

Zunjar Steel |

Hupri |

|

Saf Yeast Co.Pvt.Ltd. |

Chiplun |

Sai Steels |

Ichalkaranji |

|

Kamat Constructions |

Goa |

Chandan Steel Yard |

Kolhapur |

|

Indocount Industries Ltd. |

Kolhapur |

Nakoda Traders |

Gadhinglaj |

|

Tridentia Developers |

Goa |

Madhukar Vithal Herwadkar |

Belgaum |

|

CRG Infratech Pvt. Ltd. |

Gadhinglaj |

Shri Ramvijay Traders |

Eksamba |

|

Edcon Real Estate |

Goa |

Manik Hardware Pvt. Ltd. |

Ichalkaranji |

|

Kapson Textiles Corporation |

Davagere |

Hindustan Steels |

Kolhapur |

|

Uni Abex Alloys Pvt. Ltd. |

Dharwad |

Hariram Steel |

Kolhapur |

|

Bhima Builders & Developers |

Kolhapur |

Manish Steel Centre |

Kolhapur |

We are accepting inquiries from Goa, Karnataka and Maharashtra.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free